PRODUCTIVITY. RELIABILITY. DEVELOPMENT.

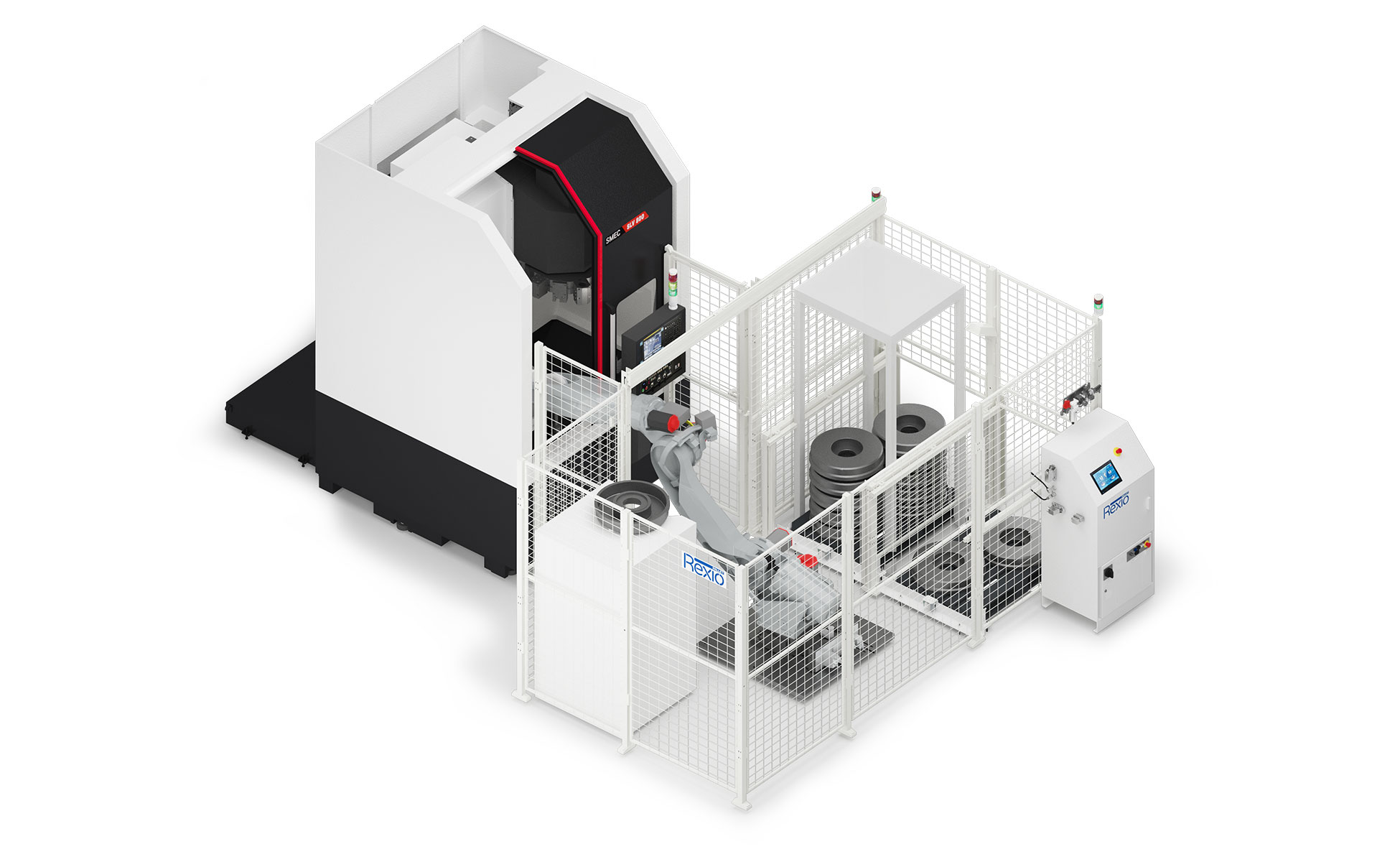

Constant development and investment in innovative solutions allow companies not only to increase their profits but also to stay ahead of the competition and to create new market standards. Choosing REXIO® robotics and automation systems is a step in the right direction. Why? Because it can improve your processes, guarantee accuracy and eliminate downtime, faults and inaccuracies. Your company will also benefit from a quick return on investment, higher profits and increased customer satisfaction.

TURN-KEY SOLUTIONS, SUPPORT AND ON-SITE COMMISSIONING

We offer comprehensive turn-key solutions including a specific-product manufacturing cell design, production, implementation, training and post-sales services.

AUTOMATION PROVIDES:

Increased productivity |

Reduced costs |

Improved production flexibility |

Increased safety |

Quick return on investment |

and competitive advantage |

CLIENT TESTIMONIALS

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Metal Team: Why did you decide to purchase a REXIO® robotic pallet system?

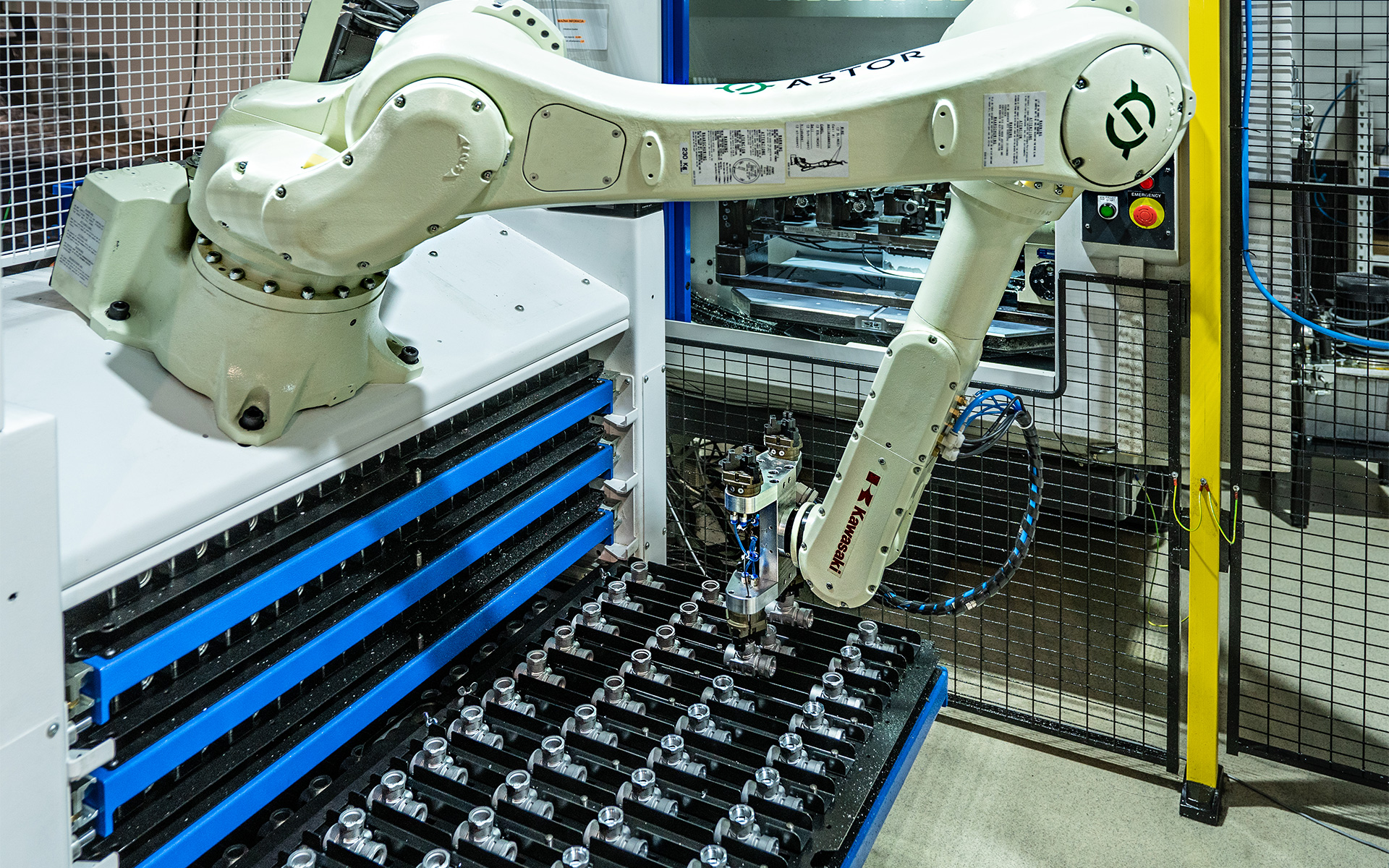

Kęty Group: An increase in the number of orders and need to improve quality forced us to look for new technological solutions. We had issues with process repeatability in the past and we wanted to develop, increase our production levels and efficiency. After the market analysis we’ve decided to contact Metal Team. We’ve watched several REXIO® systems at work and encouraged by the professional approach of Metal Team we’ve decided to invest.

Metal Team: How was REXIO® system implemented in your company?

Kęty Group: We’ve placed an order after agreeing upon all the financing and lead times. At the design stage, we’ve held many meetings and we were positively surprised by the professional approach of Metal Team staff. We’ve provided details on our processes and products to get the best production cell possible. The cell was installed without any problems and the price included a professional training on cell operation.

Metal Team: What has changed after installation of REXIO® robotic pallet system?

Spinko: We’ve noticed the improvements in the end product quality due to excellent process repeatability offered by the robot. However, the most noticeable change was an increase in process efficiency and elimination of machine downtime. Our clients are impressed by our investment and are certain that our products will be of the highest quality and on time. We became a supplier that can now guarantee future and stable deliveries.

Metal Team: Would you recommend REXIO® robotic pallet system to other manufacturers?

Spinko: Of course, Metal Team offers an individual approach for all clients both at the cell and workpiece design stage. After the installation, we’ve had a minor failure due to operator error that was quickly fixed by Metal Team – an employee also followed up after a week to make sure everything was working fine. Any manufacturing company that wants to develop must consider process automation to stay ahead of the competition.