Compact Robotic Pallet System for CNC

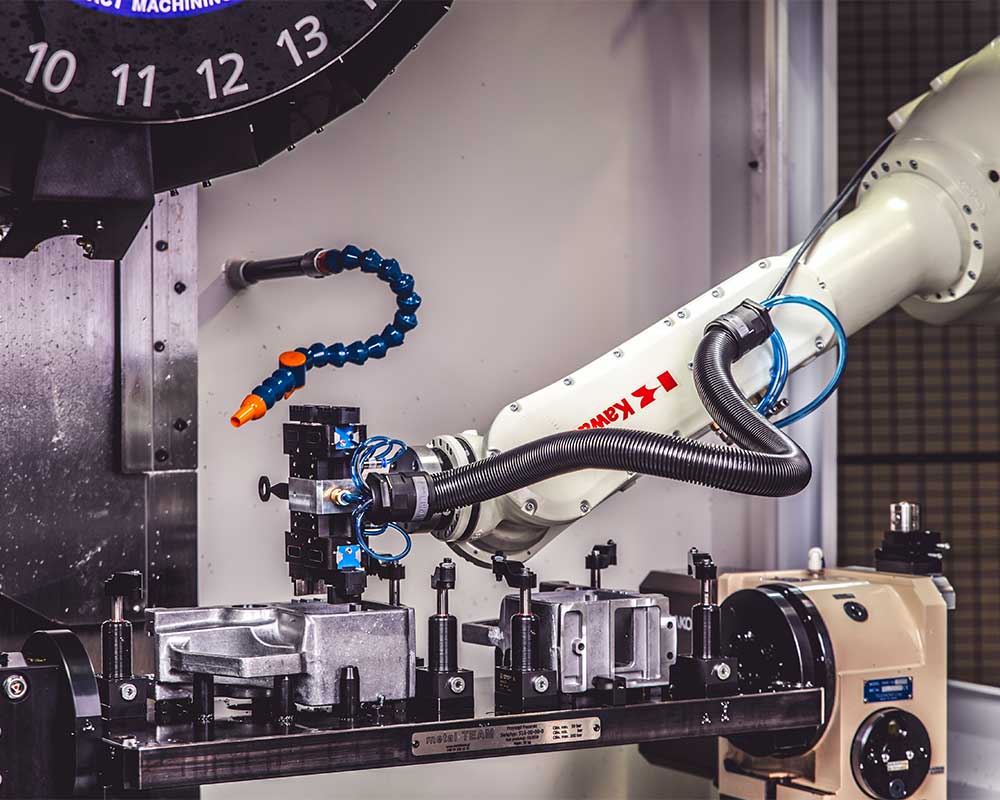

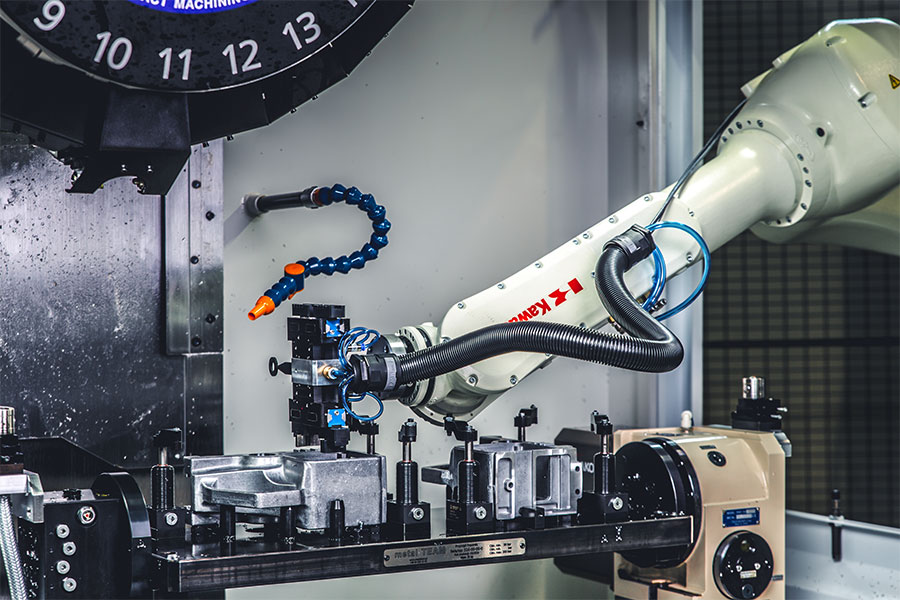

Our REXIO® DRAWER robot pallet cell is a result of an extensive experience and innovative know-how developed in response to the 21st century manufacturing market demand. The system perfectly matches the prevalent trends and its mobility, flexibility, efficiency and easy integration with available machines (in particular CNC machines) guarantee increased cost-effectiveness and improved manufacturing process. A perfect solution for clients relying on development and the modern nature of their companies.

INCREASE PRODUCTIVITY AND EFFICIENCY OF MACHINES AND PERSONNEL

With optimal task distribution, REXIO® DRAWER guarantees efficient use of human potential at different production stages. One operator can operate up to 4 machines with REXIO® DRAWER pallet system and focus on replacing the machined products with blanks, on accurate quality control of end product and on preparing the machine or on other tasks that require an individual approach.

SIMPLE STEPS

TO AUTOMATION

|

SIMPLE STEPS A CLOSER LOOK AT OUR REXIO® DRAWER SOLUTION! |

|

GENERATE SAVINGS AND INCREASE PROFITS

Unlike a standard ‘robot+feeder’ system, REXIO® DRAWER with its mobility and short implementation time on CNC machines allows to quickly use the system to manufacture parts on different machines, based on the current demand. REXIO® solutions eliminate downtime and offer substantial profits after just several months of operation.

USER-FRIENDLY AND INTUITIVE INTERFACE

A high-quality HMI control panel guarantees quick and easy operation.

An intuitive interface allows even employees without experience and know-how in robotics to work with the device while easy to use program creator reduces the retooling time to a minimum.

The connections between the robot, the machine and the external devices allow the production cell to be controlled from one place.

GENERAL SPECIFICATIONS

| No. of pallets | 3 – 6 |

| Pallet dimensions | 950 x 600 mm |

| Compatible robots | Fanuc, Kawasaki |

| Pallet load | max. 120 kg |

| Workpiece height – 6 pallets | max. 85 mm |

| Workpiece height – 3 pallets | max. 205 mm |

| Overall dimensions | 1300 x 800 x 2300 mm |

| Device weight – 6 pallets and robot | 950 kg |

| Robot weight | max. 300 kg |

| No. of pallets 3 – 6 |

| Pallet dimensions 950 x 600 mm |

| Compatible robots Fanuc, Kawasaki |

| Pallet load max. 120 kg |

| Workpiece height – 6 pallets max. 85 mm |

| Workpiece height – 3 pallets max. 205 mm |

| Overall dimensions 1300 x 800 x 2300 mm |

| Device weight – 6 pallets and robot 950 kg |

| Robot weight max. 300 kg |

- 3 pallets 990 x 600 mm, max. 40 kg/pallet

- Kawasaki or Fanuc robot, 10 kg payload with operating space limiting

- coolant drip pan (under pallets)

- perimeter safety fencing, 2.5 m long, 2.3 m high – cat. 4 safety rating

- pneumatic gripper and blow-off connection

- REXIO® coating RAL 9003

- main controller

- EC declaration of incorporation, operation and maintenance manual

- remote deployment support

- pallet 990 x 600 mm, max. 40 kg/pallet

- pallet 990 x 600 mm, max. 120 kg/pallet

- pallet workpiece separator for specific application

- workpiece blow-off station

- workpiece deburring station with flexibility adjustment

- on-demand part inspection station

- dipping station

- vision system

- workpiece re-grip station

- 3-colour signal tower lights

- custom robot grippers

- HMI control panel

- Kawasaki or Fanuc robot with up to 35 kg payload

- security scanner instead of a perimeter safety fencing

- design, installation, set-up, CE certification

REXIO® DRAWER KEY FEATURES & BENEFITS